SmartPlant Instrumentation Crack is the instrument develop especially for engineering problems, in the industry of production. Moreover, this software has been increase with features based on feedback, from Intergraph customers. This shows hard work of Intergraph’s, to providing optimal solutions that are the needs of businesses. This software was develop by Intergraph but now it has been the part of Hexagon PPM. This software is mostly used by famous companies such as oil, gas, petrochemicals, power generation and others.

SmartPlant Instrumentation Overview

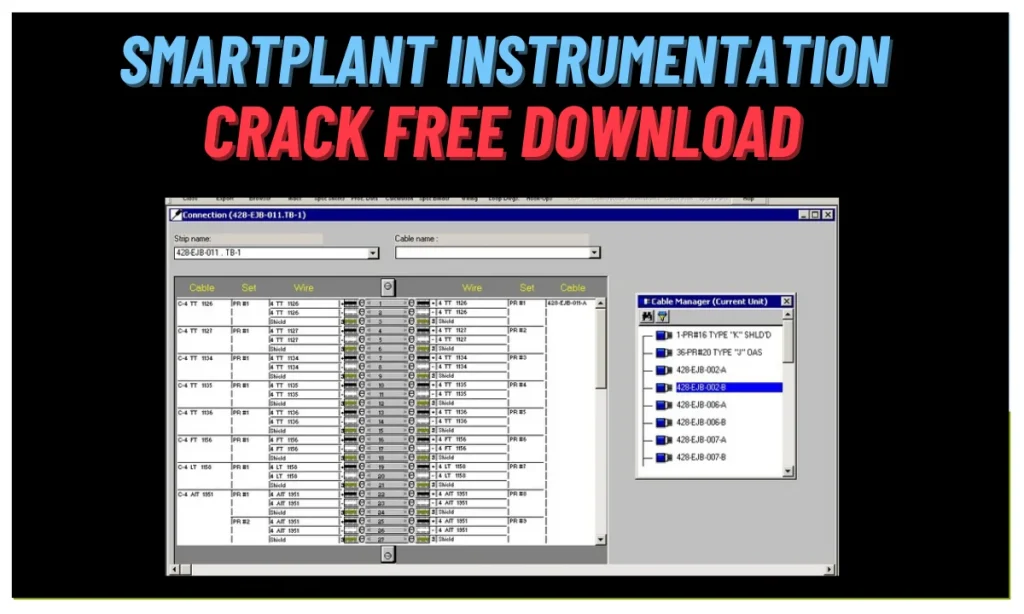

SmartPlant Instrumentation offers features that significantly improve the efficiency and quality of engineering, procurement, construction and operations, for both owner operators and EPC companies. This software enhances the functionality of the To Do List with user controls and management tools. Sometimes engineer’s got to forget where the connections are connected this software will generate loop for wire so that you can easily detect where the weirs are unified. This feature will solve half of your problem.

The To Do List promotes communication between engineering tasks across disciplines. SmartPlant Instrumentation Software Crack introduces task types such as Marked for Deletion, Overwrite and Regenerate for the To Do Lists resulting in enhanced performance. Users now have the ductlity to add custom Unit of Measures according to their needs. In SmartPlant Instrumentation is a leading solution in instrument engineering that incorporates abilities based on feedback, from Intergraph’s customers.

Furthermore this software will store all the information about instruments, its specification or all documents about it to. This interesting feature ensure the success and regularity in your working projects or later you are going to work. This software not only stop here it will gave you tags or specific key for every single instruments this make sure that you now you cannot mix your instruments with other or if you lose some of them it will alert you about it.

Key Features

- The leading engineering solution, in the industry has been further improved based on feedback from Intergraph SmartPlant Instrumentation customers.

- This demonstrates SmartPlant Instrumentation commitment to providing effective solutions that address business needs.

- The solution now offers features that boost productivity and enhance the quality of engineering, procurement, construction and owner operator companies.

- The To Do List has been upgraded with user controls and management tools to ease communication between engineering tasks.

- Additionally new task types such as Marked, for Deletion Overwrite and Regenerate have been introduced to significantly improve performance.

- Clients also have the ability to easily add custom Unit of Measures while users can define their custom units calmly now.

Related Articles

- DMG Audio Crack Free Download 2023

- TuneFab Spotify Music Converter Crack Free Download 2023

- iZotope Vocal Doubler Crack Free Download 2023

- Autodesk AutoCAD Mechanical Free Download

- DigiDNA iMazing Crack Full Download 2023

System Requirements

- Operating System: Windows XP/Vista/7/8/8.1/10

- Recommended Processor: Intel Dual Core processor or later

- Recommended Ram: 1GB

- Hard Drive Space: 700MB

SmartPlant Instrumentation Crack Conclusion

SmartPlant Instrumentation Software Free Download proves to be an asset, for companies engaged in the planning, building and upkeep of industrial facilities that heavily rely on precise instrumentation and control systems to ensure safety and optimize efficiency. Hence, This tool streamlines project workflows, minimizes mistakes and the human error. This software Enhances the excellence and dependability of instrument and control system designs. Download this amazing software now link is given below:

![Citavi 6.8.0 Crack Free Download [2024] Citavi Crack](https://miwanistore.com/wp-content/uploads/2023/10/Citavi-Crack-218x150.webp)

![MobiKin Doctor 4.2.82 Crack Free Download [2023] mobikin-doctor-crack](https://miwanistore.com/wp-content/uploads/2022/11/MobiKin-Doctor-Logo-4922311.png)

![Max Payne 2 Crack Free Download [2023] max-payne-crack](https://miwanistore.com/wp-content/uploads/2022/11/Max-Payne-Logo-1043869.png)